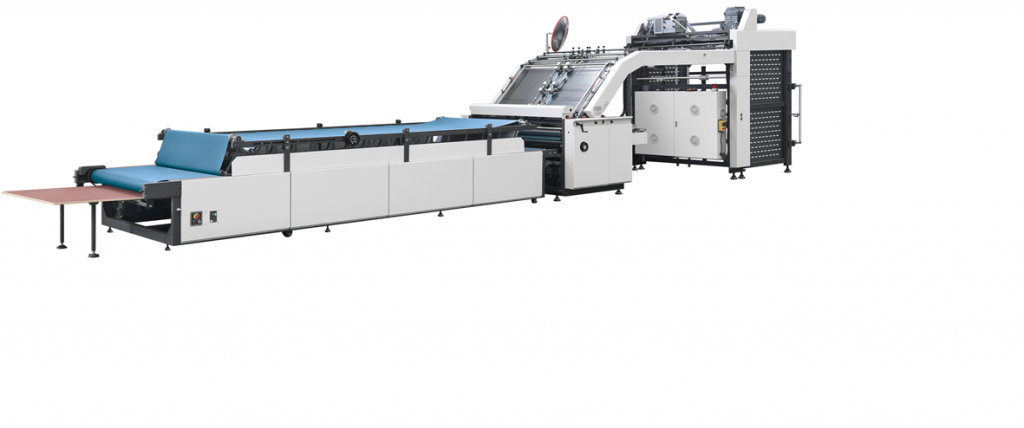

Automatic case making machines

Cases the corrugated boards:

- single-wall corrugated board with single-wall corrugated board

- single-wall corrugated board with double-wall corrugated board in C, B, E, and F flutes

- single-wall corrugated board with 3, 4, and 5-layered corrugated board”

The bottom sheet is automatically fed by the vacuum belt feeder, and then it passes under the glue applicator roller, which applies glue to its surface. The top sheet is also automatically fed using suction cups from a pallet located on a lift. The machine allows for the adjustment of glue quantity. It can glue up to 12,000 sheets per hour. The registration is achieved using servo motors. We offer more economical models with a production capacity of 7,000 sheets per hour and mechanical registration.

Both types of casemakers can be ordered in various working formats. It depends on the customer’s needs and budget. Popular machine formats include 1300×1300 mm, 1300×1480 mm, and 1650×1650 mm.

There is also an option to order a “flip-flop” delivery. After the glued sheets come out of the machine, they need to be stacked on a pallet. With an automatic flip-flop device, the casemakers will do this automatically, stacking the glued sheets.

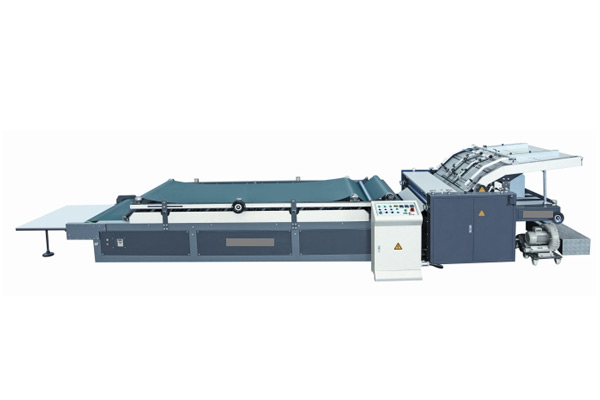

Semi-automatic casemakers

It glues cardboards:

• Single-faced cardboard sheet with single-faced cardboard sheet

• Single-faced cardboard sheet with double-wall cardboard sheet in C, B, E, and F flutes

• Single-faced cardboard sheet with 3, 4, and 5-layer cardboard sheet

The gluing of the sheets is very precise, allowing for the production of high-quality casemaking packages or advertising materials. The operation of this machine is as follows:

The bottom sheet is automatically fed by a vacuum belt feeder and passes under a roller that applies glue to its surface. The top sheet is semi-automatically fed, meaning it is manually positioned against a photocell that triggers the guiding rollers. Then, both sheets are aligned and joined together. The machine features electronic adjustment for sheet alignment. The joined and glued sheets are placed on a pressure table where final even and accurate bonding takes place. The machine can glue up to 3,000 sheets per hour.

The machine can be ordered in various working formats depending on the customer’s needs and budget. Popular working formats include 1300×1300 mm, 1300×1480 mm, and 1650×1650 mm.