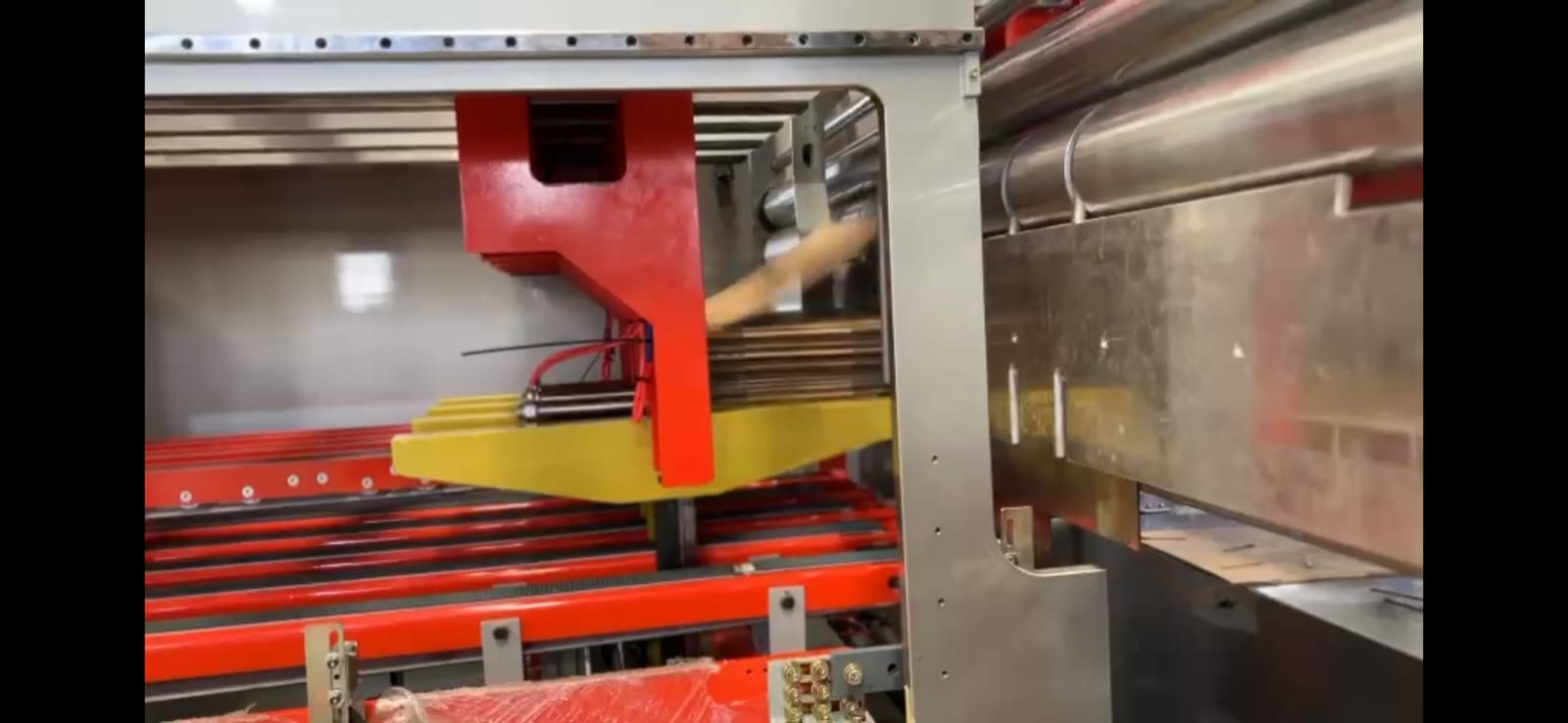

Linia do produkcji opakowań kartonowych może być skonfigurowana dokładnie pod wymagania klienta. Możemy skonfigurować samą drukarkę, gdzie maszyna będzie składać się z samych segmentów drukujących i podajnika, lub zbudować maszynę, która będzie dodatkowo wyposażona w np. w sloter i rotację. Poszczególne segmenty także konfiguruje się pod wymagania klienta, gdzie można zastosować prostsze tańsze rozwiązania lub zainwestować lepszą technologię. W przypadku podajnika rozróżniamy parę ich modeli, a mianowicie najprostszy podajnik łańcuchowy, podajnik listwowy lub rolkowy. Drukarki mogą być proste wyposażone w wały rastrowe stalowe i wał gumowy lub zamiast wałów stalowych wały ceramiczne. Technologią, która zapewnia najdokładniejsze nakładanie farby to zastosowanie listew raklowych na wałach rastrowych. Wówczas nadmiar farby jest zbierany z wału i na polimer przekazywana jest precyzyjna ilość farby.

Kolejną opcją, jaką możemy wybrać, jest sposób prowadzenia arkusza tektury przez maszynę. Gdy odbywa się to za pomocą transferu podciśnieniowego mamy wówczas pewność, że pasowanie poszczególnych kolorów będzie na wysokim poziomie, co pozwoli na drukowanie obrazów składających się z wielu kolorów.

Inną opcją są jeszcze sekcje czyszczenia arkusza tektury tuż po wycięciu oraz układanie ich przez maszynę zwaną stackerem .

PARAMETRY TECHNICZNE

Możemy zaoferować różne wielkości maszyn z różnymi szerokościami i obwodami wałów .

Dla przykładu możliwe obwody w mm : 600/900/1200/1400/1600/1800/2000

Przykładowa tabela z parametrami technicznymi .

| Model | 1200 | 1400 | 1600 |

| Szerokość maszyny | 1200*2400/2600/2800/3000/3600/4200/5000 | 1400*2400/2600/2800/3000/3600/4200/5000 | 1600*2400/2600/2800/3000/3600/4200/5000 |

| PRĘD. MECHANICZNA | 180 | 180 | 180 |

| PRĘD. PRODUKCYJNA | 150 | 150 | 150 |

| Min format arkusza | 350*650 | 350*650 | 420*650 |

| Skip feeding size | 1400*2050/2250/2450/2650 | 1600*2050/2250/2450/2650 | 1800*2050/2250/2450/2650 |

| Grubość tektury | 2-11 mm | ||

| Max pole zadruku | 1200*2000/2200/2400/2600 | 1400*2000/2200/2400/2600 | 1600*2000/2200/2400/2600 |

| Grubośc montażu polimerów | 7.2 mm | ||

| Regulacja osiowa wałka druk | +- 5 mm |